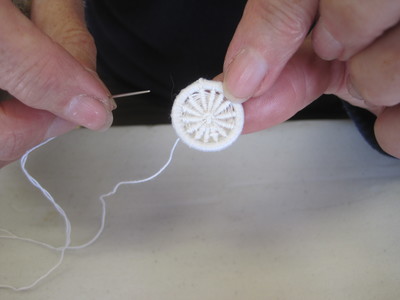

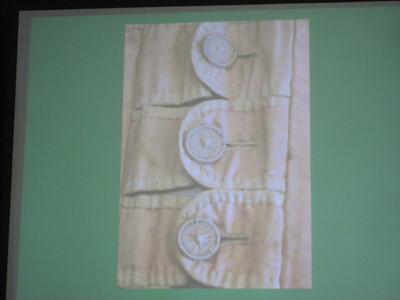

The day after Anna McDowell's interesting talk about the history of Dorset buttons she kindly taught a group of Guild members the various techniques to enable us to create our own buttons. Everybody was given a pack which included the metal ring, thread and the instructions to make a Dorset "cartwheel" button. I was surprised to learn that you used one length of thread and, to begin with, I found 3 1/2 yards quite difficult to handle without getting into knots! Our second button was the Daisy pattern which was worked on a larger metal ring but this had a staggering 5 1/2 yards. We all managed with some results better than others! The final button we were shown was called the "singleton" and for a group of embroiderers this button opened up a great opportunity to express ourselves. By the end of the day, everybody had at least two buttons and some speedy people even had three!

Thank you Anna for a most enjoyable day. Report by Ros

0 Comments

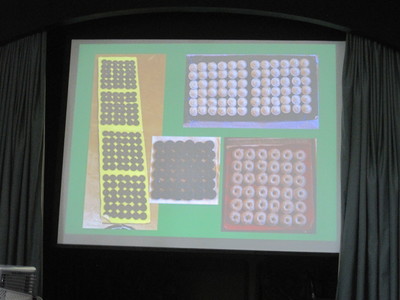

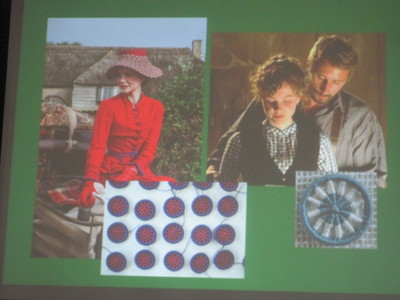

Anna McDowell started her talk by explaining that Dorset buttons started as a love story. A soldier, Abraham Case went to the continent in 1600s and brought back this technique of making buttons. When he returned he went to Wardour Castle and fell in love with a local girl and they set up the Dorset Button industry.  High tops were the first to be made from a disc of sheep’s horn, fabric and thread. Dorset Knobs came after along with the Blanford cross wheel and various other designs. The business grew rapidly as a Cottage industry with women and children working in their own homes and in 1730 Abraham’s grandson Peter took over the company and it is thought introduced metal rings. John Clayton joined and organised it as a proper industry. Anna showed us a record sheet from the Blanford Workhouse which showed what a profitable business it was. In 1793 it was recorded that 5d per gross was paid for the buttons and 4000 people in and around Shaftesbury were involved and 3000 around Blanford. In 1812 people were paid 9d per day to work on the land at harvest time but they could earn 12 – 18d per day making buttons.  Men of fashion including Beau Brummel would wear up to 24 shirts a week all done up with Dorset buttons so the industry thrived. The buttons were made in neutral colour thread and dyed after to match a ladies dress or blouse. In 1812 Benjamin Saunders patented the first mechanised button machine and this heralded the beginning of the end for the hand-made button industry. Anna’s interest began when she became chair of the Gold Hill Museum in Shaftesbury and since then she has tried to bring the Dorset Buttons into the 21st century demonstrating the making of traditional and contemporary buttons. Anna has a website which gives details of the history, she gives workshops and undertakes commissions for making Dorset buttons for period costumes.

|

AuthorInformation in this blog is provided by branch members who have attended the meeting, workshop or event. Categories

All

Archives

October 2017

|

|

Marlborough & District Branch is a member of the Embroiderers' Guild, the UK's leading crafts association

* The Embroiderers' Guild website -https://embroiderersguild.com/ * The Guild Facebook page - https://www.facebook.com/embroiderersguild/ * The Guild Pinterest pages - https://uk.pinterest.com/theembroiderers/ |

design by chrisse

|

RSS Feed

RSS Feed